Ball Bearings Guide

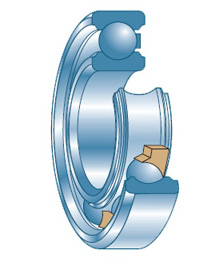

Ball bearings are small and hard steel balls placed between moving parts of a machine so that the parts can move smoothly. They reduce rotational friction and supports axial and radial loads. There is minimal contact of the balls with the inner and outer races because of their spherical shape, which is why they can spin smoothly.

They have a simple design, are extremely durable, and can be maintained easily. The bearings can be of many sizes. Some of them are smaller than a grain of rice that can be fitted inside a wristwatch, and there are ball bearings that have a diameter of one meter for power plant and factory applications. There are single and double row ball bearing designs, and sealed and open variants.

Construction

The construction is simple. There are four main parts –

- Outer ring

- Inner ring

- Ball Separator (Retainer)

- Rolling Bodies (The Balls)

| Outer ring | Inner ring | Ball Separator | Rolling Bodies |

|---|---|---|---|

|

|

|

|

The Outer Ring

This is the larger of the two rings. In the inside diameter here, there is a groove that forms a pathway for the balls. It is shaped in such a way that the balls can stay a bit loose in the groove. The balls have just a single point contact on each race because of this loose fit. This reduces friction. The outer ring stays stationery.

The Inner Ring

This is the smaller ring, mounted on the shaft. The groove is on the outer diameter here, whereas in the outer and larger ring, it is on the inner diameter. The groove forms a path for the balls. Surface of the outside diameter is extremely smooth and has high tolerance. It has the same high precision finish like the surface of the outer ring. The inner ring is essentially the bearing’s inner circle structure where the balls spin or rotate. Inner races are typically made of ceramic or steel in most spinner bearings.

Retainer

Also called the ball separator or the cage, its purpose is to keep the balls within the two outer and inner rings separated, maintain a constant space between the two rings, guide the balls accurately in the correct path during rotation, and to prevent the balls from falling off. Cages also lubricate the bearing through a coating on the edge. Ball separators are selected based on the size of the bearing, and the performance required.

Balls

These are the rolling bodies located between the two rings, held by the cage or the retainer. The balls are what make the bearing rotate with very little friction. But it is important to remember that there may not be any cages as well. For instance, a model may not have a ball separator if there are enough balls that fill more than half the circumference of the bearing, which makes them stay in place. The ball’s radius is slightly smaller than the outer and inner ring ball tracks. This is what makes the balls have contact with the rings at a single point. The surface finish, size, and ball roundness are all very important. The balls are made of different ceramics and metals, but the most common in chrome steel.

Lubrication

This is also an important component of the bearing. Lubrication is applied so that the friction loss between the outer and inner rings can be reduced.

Optional Components of the Bearing

There are some other components like seals and shields that improve the life and performance of ball bearings. These are optional components, added to the bearing depending on the requirement of the customer.

Shields – This is a profiled and stamped sheet metal disc that prevents large particles from entering the bearing. The shield is pressed on the outer rings inside diameter. There will be a small gap between the shield and the inner rings diameter. There is no friction between the bearing and the shield as it doesn’t touch the inner ring, and as a result the bearing has a very low torque.

Seals – This is also inserted within the outer rings inside edge diameter. The seal’s inner edge is molded into a lip configuration, which is specifically designed. They snap-fit easily into the ring.

Types of Ball Bearings

There are three main types of bearings. They are –

- Radial Bearings

- Angular Contact Bearings

- Thrust Bearings

Radial Ball Bearings

They are designed so that they can carry both axial and radial loads. Thrust bearings on the other hand are designed just for thrust loads. Also called deep groove bearings, they can take both the loads to varying degrees, but are primarily used when the main load is in radial. These bearings are extremely popular.

Deep Groove Ball Bearings

Deep groove radial ball bearings are some of the most common ones. They are used for transmitting loads from rotating parts to housings with very little friction loss. This is obtained by making sure that there is very little deformation in the bearing elements. Design measures like precision, materials, and radial clearance ensures that the rolling action is undisturbed. Both the outer and inner rings have flat surfaces, so there is a larger contact. This allows high radial load capacity and works well for high speeds. There is low torque capacity at startup and running speeds. They emit low noise, and need little maintenance. The axial load capacity is in both directions.

These bearings are used in many industries including high precision apparatus and heavy machinery.

- Deep groove ball bearings are popular with electric motor manufacturers and motor refurbishments. But it is important to select the right bearing as there are different types of motors.

- In general machinery, these bearings are found in gearboxes, pumps, and compressors. Demands on the bearings vary, depending on the machinery.

- These are also important components in electrical goods too like washing machines and photocopiers. The specification is critical.

There are four main types of deep groove radial ball bearings. They are Single Row Bearings, Extra Small and Miniature Ball Bearings, Maximum Type Bearings, and Magneto Ball Bearings.

Angular Contact Ball Bearings

They are designed in a way to reach high speeds and withstand radial-axial loads. But they can withstand only unidirectional axial loads. They are good for moderate radial loads and heavy thrust loads. When used, these bearings form a contact angle between the balls and the races when used. A major characteristic of the design is that, one shoulder of one or both of the ring races are always higher. For proper functioning, they have to be assembled with a thrust load, which creates a contact angle between the outer and inner races, and the ball. The contact angle can vary between 15° and 40°. The races and balls are typically made of chrome steel. However, sometimes ceramic balls are also used, especially when the operating conditions are severe.

Single Vs. Double Row Angular Bearings – Angular contact bearings are mounted usually in groups of two or more. This is done by matching several single row bearings or by using double row bearings, which is often preferred for economic reasons. But the performance and design flexibility in many cases is better with single row mounts.

Thrust Ball Bearings

Like other ball bearings, they allow rotation between the parts, but they are best used for pure thrust loads. They are unable to handle radial loads. Roller, needle, or a ball can be the rolling element. These bearings are mounted directly on the seating surface and not the shaft or the housing. There are mounting holes on the outer and inner rings, and there can also be integral gears on both the rings, or in any of them. Oil lubrication is necessary for higher speed applications. Typically, these bearings work at lower loads and higher speeds.

Precision Ball Bearings

Operating Specifications

When buying bearings, there are some important operating specifications that need to be considered. They are,

- The rated speed

- Thrust or dynamic axial load

- Dynamic radial load

Rated Speed – The bearing’s rated speed running with oil lubrication will be higher than one working with grease lubrication.

Thrust or Dynamic Axial Load – This is the calculated constant axial load that a group of bearings can theoretically endure 1 million revolutions in its rating life.

Dynamic Radial Load – This is the constant radial load that a group of bearings can theoretically endure 1 million revolutions in its rating life.

Performance Characteristics

Low-Friction Operation

Reduced friction will allow efficient energy transfer, low erosion, and more longevity. The ball bearings of today can perform better, thanks to progress in the bearing technology, the use of new materials, bearing shapes, electromagnetic improvements, and fluid dynamics. The bearing material technology has improved from wood, iron, steel, to the latest low-friction plastics. There is a fluid barrier, and even electromagnetic field in many bearings that provide very efficient performance. The service life is also improved greatly. Often, many techniques like specially-shaped plastic bearings with a fluid barrier combine to deliver the best performance.

Load Capacity

Load capacity of the bearing is as important as its ability to reduce friction. Heavy machinery, such as manufacturing equipment, conveyor belts, and vehicles, for example, need different types of ball bearings that are able t handle heavy loads. Precision and speed is sometimes sacrificed, but it is worth it, if greater loads can be accommodated. The direction of force also needs to be considered, because the force can come from different directions – axial, radial, bending movements, or in a combination of them. There are different bearings for managing different movement types.

Speed Capacity

The operating speed is also very important. Speed is measured as the maximum relative surface speed, by using meters or feet per second. Performance is also noted as rotations per minute and the bearing diameter (D*N). A higher result means greater speed capacity. There are different bearings for speed capacities. However in practice, there is often an overlap, so there are always choices. But high speed applications usually prefer fluid or magnetic ball bearings. Those with rolling elements are best for mid-range speeds, while plain ball bearings may give good results for low speed applications.

Bearing Load, Lifespan, and Fatigue

The bearing life will be optimum only when there is minimal surface contact of the raceways and the balls. There has to be proper lubrication as well. The bearings are subject to dynamic or static loads, and also radial or axial loads, which means, it is necessary to account for four variables for determining the working loads. Typically, the bearings can handle more dynamic and radial loads than static or axial loads. Usually, the first sign of a deformation will be flat spots on the balls, which prevents smooth rotation.

The bearing’s life depends on its operating speed, environmental factors, and load. Accepted industry standards are that 90% of the bearings can still be serviced even after 1 million rotations, and 50% of them can be serviced after 5 million rotations. This is called the bearing fatigue life.

Bearing Precision

The most important functions of ball bearings are to bring down friction, and allow smooth rotation. Modern day bearings are extremely precise. To achieve this, the groove where the balls roll needs to be a perfect circle. This is a major element of making an extremely precise ball bearing.

How much friction can the bearing reduce for easy and smooth rotation? This is always the most important performance measure. Ball bearings are used in automobiles, precision medical equipment, aircraft, and in other end products, but whatever the application, they need to always minimize friction and maintain smoothness. With changing times, there are more diversifications and complexities in machine types and end products, and enhanced performance requirements like higher rotation speeds, miniaturization, noise reduction, duration, and durability.

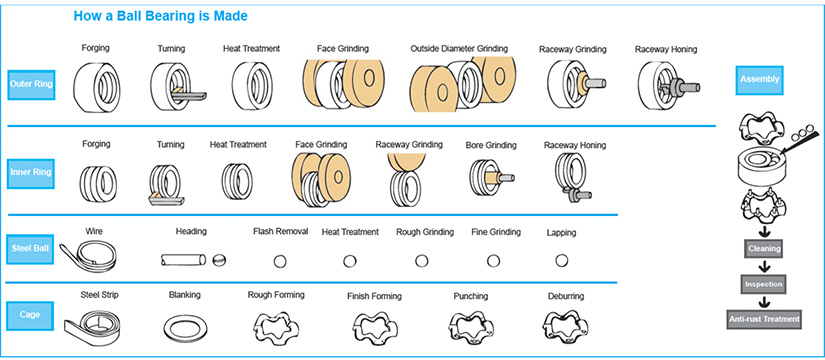

How a Precision Ball is Made

Heading: To begin, heading machines cut wire into short lengths and shape it into spherical shapes between sized dies.

Deflashing: The flash line, the lip left by the forming dies, is ground off as balls roll between heavy, cast iron plates.

Soft Grinding: Similar to deflashing, except that a fine grit grinding stone is used to improve precision.

Heat-treating: Carbon steel balls are next carburized and hardened. Heat treatment allows for the desired hardness and case depth.

Descaling: This step takes away the residues and small burrs from the heat-treating process.

Hard Grinding: Slow, methodical grinding ensures proper sizing and sphericity, with tolerances as close as ±.0001".

Lapping: There are different types of proprietary lapping processes can finish balls to the requirements of ISO 3290 Grade 10 - 48.

Finishing: State of the art chemical and mechanical processes give the precision balls their final smoothed finish for increased durability and product longevity.

Inspection: All ball bearings pass through at least two 100% inspection stages using cutting edge automated inspection techniques.

Ball Bearing Weight Chart

The following chart displays the weight of the most common sizes of chrome steel bearing balls.

| Size - Inches | Balls per pound | Weight per ball | Crush strength in pounds | Size - Inches |

|---|---|---|---|---|

| 1/32 | 221138. | - | - | 1/32 |

| 1/16 | 27642.3 | - | 270 | 1/16 |

| 3/32 | 8190.32 | - | 610 | 3/32 |

| 1/8 | 3455.29 | .131 gr. | 1100 | 1/8 |

| 5/32 | 1769.11 | .256 gr. | 1710 | 5/32 |

| 3/16 | 1023.79 | .443 gr. | 2470 | 3/16 |

| 7/32 | 644.719 | .703 gr. | 3360 | 7/32 |

| ¼ | 431.911 | 1.050 gr. | 4400 | 1/4 |

| 9/32 | 303.345 | 1.495 | 5560 | 9/32 |

| 5/16 | 221.138 | 2.051.gr. | 6870 | 5/16 |

| 11/32 | 166.144 | 2.730 gr. | 8300 | 11/32 |

| 3/8 | 127.973 | 3.544 gr. | 9900 | 3/8 |

| 13/32 | 100.654 | 4.506 gr. | 11600 | 13/32 |

| 7/16 | 80.5899 | 5.628 gr. | 13400 | 7/16 |

| 15/32 | 65.5225 | 6.923 gr. | 15400 | 15/32 |

| 1/2 | 53.9889 | 8.402 gr. | 17600 | 1/2 |

| 17/32 | 45.05 | 10.077 gr. | 18000 | 17/32 |

| 9/16 | 37.9181 | 11.96 gr. | 20200 | 9/16 |

| 19/32 | 32.26 | 14.069 gr. | 22500 | 19/32 |

| 5/8 | 27.6423 | 16.41 gr | 25000 | 5/8 |

| 21/32 | 23.86 | 19.996 gr. | 27560 | 21/32 |

| 11/16 | 20.7681 | 21.841 gr. | 30200 | 11/16 |

| 23/32 | 18.18 | 24.957 gr. | 33000 | 23/32 |

| 3/4 | 15.9967 | 1.00 oz. | 36000 | 3/4 |

| 25/32 | 14.15 | 1.13 oz. | 39000 | 25/32 |

| 13/16 | 12.5818 | 1.26 oz. | 42200 | 13/16 |

| 27/32 | 11.24 | 1.42 oz. | 45500 | 27/32 |

| 7/8 | 10.0737 | 1.58 oz. | 49000 | 7/8 |

| 29/32 | 9.06 | 1.76 oz. | 52500 | 29/32 |

| 15/16 | 8.19032 | 1.95 oz. | 56200 | 15/16 |

| 31/32 | 7.42 | 2.16 oz. | 60000 | 31/32 |

| 1 | 6.74861 | 2.36 oz. | 64000 | 1 |

| 1-1/16 | 5.63 | 2.84 oz. | 72200 | 1-1/16 |

| 1-1/8 | 4.73977 | 3.375 | 81000 | 1-1/8 |

| 1-3/16 | 4.03 | 3.970 oz. | 90200 | 1-3/16 |

| 1-1/4 | 3.45529 | 4.631 oz. | 100000 | 1-1/4 |

| 1-5/16 | 2.99 | 5.360 oz. | 104700 | 1-5/16 |

| 1-3/8 | 2.59601 | 6.163 oz. | 108900 | 1-3/8 |

| 1-7/16 | 2.27 | 7.043 oz. | 115700 | 1-7/16 |

| 1-1/2 | 1.99959 | 8.002 oz. | 122400 | 1-1/2 |

| 1-5/8 | 1.57273 | 10.173 oz. | - | 1-5/8 |

| 1-3/4 | 1.25921 | 12.706 oz. | - | 1-3/4 |

| 1-7/8 | 1.02379 | 15.628 oz. | - | 1-7/8 |

| 2 | .843577 | 1.00 lb. & 2.967 oz. | - | 2 |

| 2-1/8 | .703296 | 1.00 lb. & 6.750 | - | 2-1/8 |

| 2-1/4 | .592471 | 1.00 lb. &11.006 oz | - | 2-1/4 |

| 2-3/8 | .503760 | 1.00 lb. & 15.761 oz. | - | 2-3/8 |

| 2-1/2 | .431911 | 2.00 lbs. & 5.045 oz. | - | 2-1/2 |

| 2-5/8 | .373101 | 2.00 lbs.&10.884 oz. | - | 2-5/8 |

| 2-3/4 | .324501 | 3.00 lbs. & 1.306 oz. | - | 2-3/4 |

| 2-7/8 | .283988 | 3.00 lbs. & 8.340 oz. | - | 2-7/8 |

| 3 | .249948 | 4.00 lbs & 0.013 oz. | - | 3 |

| 3-1/8 | .221138 | 4.00 lbs & 8.353 oz. | - | 3-1/8 |

| 3-1/4 | .196591 | 4.00 lbs & 1.387 oz. | - | 3-1/4 |

| 3-3/8 | .175547 | 5.00 lbs & 11.144 oz | - | 3-3/8 |

| 3-1/2 | .157402 | 6.00 lbs. & 5.650 oz. | - | 3-1/2 |

| 3-5/8 | .141674 | 7.00 lbs. & 0.935 oz. | - | 3-5/8 |

| 3-3/4 | .127973 | 7.00 lbs. & 13.026 oz. | - | 3-5/8 |

| 3-7/8 | .115984 | 8.00 lbs. & 9.950 oz. | - | 3-7/8 |

| 4 | .105447 | 9.00 lbs. & 7.735 oz. | - | 4 |

| 4-1/8 | .096148 | 10.00 lbs. & 6.409 oz. | - | 4-1/8 |

| 4-1/4 | .087911 | 11.00 lbs & 6.000 oz. | - | 4-1/4 |

| 4-3/8 | .080589 | 12.00 lbs & 6.536 oz. | - | 4-3/8 |

| 4-1/2 | .074058 | 13.00 lbs. & 8.044 oz. | - | 4-1/2 |