What Is Cold Formed Stainless Steel

Cold formed stainless steel refers to stainless steel that has been shaped into a desired shape through a process called cold forming. Cold forming is a manufacturing process in which a piece of stainless steel is shaped at room temperature or below, using high pressure.

There are several benefits to cold forming stainless steel over other forming methods, such as hot forming or casting. Cold forming allows for the production of complex shapes with tight tolerances, as the material is less likely to deform or become distorted during the forming process. Cold forming also allows for the production of thin-walled parts with improved surface finish and mechanical properties, as the material is not subjected to the high temperatures and stresses that are present during hot forming.

Cold formed stainless steel is commonly used in a variety of applications, including automotive parts, aerospace components, and medical devices. It is also used in the production of precision balls, such as those used in ball bearings.

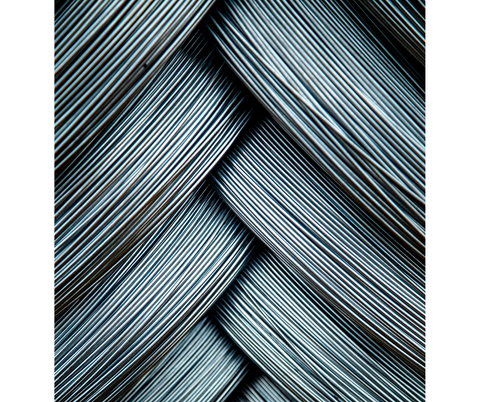

There are several different methods of cold forming stainless steel, including rolling, stamping, drawing, and forging. The specific method used will depend on the shape and size of the part being formed, as well as the properties of the stainless steel alloy being used.